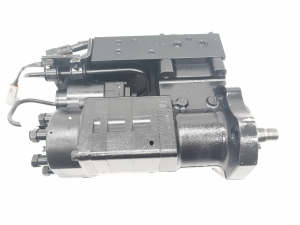

To ensure the longevity and optimal performance of the Cummins C Series Engine ISC8.3, proper maintenance of the fuel injection system is crucial. Heavy equipment owners rely on Cummins spare parts, such as the Fuel Injection Pump 4076442, 4076442X, and 4076442RX from Kuduparts, to keep their equipment running smoothly. This article provides essential guidance on maintenance practices, regular inspections, and troubleshooting tips for addressing common fuel injection pump issues effectively.

Regular Inspections for Optimal Performance

Regular inspections of the fuel injection system are essential to identify potential issues early on and maintain optimal performance. Equipment owners should inspect fuel lines, connections, and seals for leaks, ensuring they are secure and in good condition. Additionally, it is essential to check for any signs of fuel contamination or blockages that may affect fuel delivery. By conducting routine inspections, equipment owners can address minor issues before they escalate into major problems.

Servicing and Cleaning for Longevity

Proper servicing and cleaning of the fuel injection system are vital for its longevity and efficient operation. Equipment owners should follow the manufacturer’s recommended maintenance schedule, which includes periodic servicing of the fuel injection pump. This involves cleaning or replacing fuel filters, inspecting and adjusting injector nozzles, and maintaining proper fuel pressure. By adhering to these maintenance practices, heavy equipment owners can maximize the lifespan of their Cummins spare parts.

Troubleshooting Common Fuel Injection Pump Issues

Despite regular maintenance, fuel injection pump issues may arise. Two common problems include insufficient fuel delivery and erratic fuel pressure. In the event of insufficient fuel delivery, equipment owners should check for clogged fuel filters or restricted fuel lines. If erratic fuel pressure occurs, it may be due to a faulty pressure regulator or worn-out pump components.

Conclusion

Proper maintenance and troubleshooting practices are vital for the optimal performance and longevity of the Cummins C Series Engine ISC8.3. Heavy equipment owners can rely on Cummins spare parts, including the Fuel Injection Pump 4076442, 4076442X, and 4076442RX from Kuduparts. By conducting regular inspections, adhering to recommended servicing and cleaning procedures, and effectively troubleshooting common fuel injection pump issues, equipment owners can keep their heavy-duty machinery operating at peak performance levels.